Special solution

The PrioLine® concept is based upon special profiles.

Additionally, we offer you a wide selection of customized enclosure

solutions made of plastic and metal.

Challenge us and send us your requirements and your ideas!

We will help you to find a reasonably priced, efficient solution!

Metal

Customized case for medical device

Problem:

Separate display- and operating units

for a medical device had to be designed

as customized versions. Both had to be

mounted onto a trolley provided by the

customer.

Solution:

Construction and preparation of drawings on the basis of customer-provided circuit

boards and mounting-parts. Operating and machine enclosure as bent and welded

aluminum construction

Contact surfaces chromated (electrically conductive)/ visible surfaces chemically

resistant and varnished in silver.

PrioLine HD - „Heavy Duty“ for demanding applications

- dimensions:

ca. B: 385,0 x H1: 85,0 x

H2: 265,0 x T1: 350,0 x

T2: 25,0 mm - Heavy Duty

- plates outside flush-fitting

to the profile - painted RAL 7035

- cover plate with cutout 149,43 x 265,66 mm

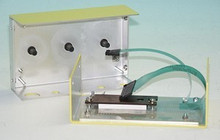

Enclosures for thermal control unit

- made of aluminium 3 mm, executed as weldment/bent component

- apertures acc. to customer specifications

- without visible screws in using position

- surface: 2-colour varnish acc. to RAL

- 3-colour printing

(front-, back- and support plates and on the perforated plate) - incl. INSERT PLATE, replaceable

- with 4 back side threaded bolts

Customized enclosure for a dental device

Problem:

A display and operating unit for a dental device had to

be designed as a customized version.

- console-shaped

- construction on the basis of circuit boards and

mounting-parts provided by the customer - easy to clean, no rough edges

- mounting possibility for an easily accessible

EMERGENCY-OFF-switch - easy integration of the components

and circuit boards - NO visible screws from the outside

- lockable

- good EMC properties

- chemically resistant surface

- integrated operating-/display unit

- available on short notice

Solution:

Operating and machine enclosure as bent and welded aluminium construction. Contact surfaces chromated (electrically conductive)/visible surfaces chemically resistant and varnished in silver (multi-layer technique). Input via a customized foil keyboard flush with the front, where the display window is also integrated in a waterproof manner. Manufactured and delivered in express service.

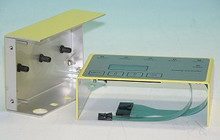

Enclosure for monitoring device

Problem:

A display and operating unit for a monitoring device had to be

designed as a customized version.

- enclosure with customized dimensions and fixing devices

- easy assembly, flat and space-saving integration of the components

and circuit boards required for display and operation - good EMC properties

- customer-specific surface

- display back lighting not by means of EL-foil, but as LED-unit

Solution:

- aluminium enclosure as 2-parts bent aluminium construction

- contact surfaces chromated (electrically conductive)/

visible surfaces varnished in yellow - fixing parts and apertures acc. to customer specifications

- input via a customized foil keyboard in the cover

- the windows as well as the display itself are integrated in a

dust- and waterproof manner, the same applies to the LCD controller.

Extremely compact and space-saving assembly in

FOILtronic®-technique. - back lighting unit for LCD on the basis of LED-light guides

- display and back lighting system are protected against

being pushed through/mechanical influences - contacting of LED, LCD and keys via integrated foil cable

with crimped sockets

Customized enclosure for laptop-accessory device

- B300 x T290 x H75 mm

- incl. apertures

- incl. fixing parts

- incl. surface

- incl. foil keyboard

Customized enclosure for medical device

A customized table enclosure for a medical device was required.

- rugged, heavy duty construction

- customized execution

- good EMC properties

- chemically resistant surface

- integrated maintenance flap in the bottom part

- rear fixing device for optional TFT-display-enclosure

Enclosure for a medical device, complete with control unit

Enclosure:

- arried out as aluminum bent component

- T300 x B266 x H92 mm

Special features:

- no visible screws in using position

- bottom part inserted into lid grooves

- enclosure stackable (continuous fixing rod, cups in the lid)

- foil keyboard can be mounted flush with front side

- incl. apertures, bore holes, counterbores

- incl. lateral flap

- SPECIAL FEATURE:

- no visible hinges inside /outside

- back side cord sealing

- lockable (lock incl. 2 keys)

- supplied incl. accessories (battery support, battery holder)

- good EMC-properties (chromated electrically conductive)

- outer surfaces varnished in RAL 9005 fine structure)

Foil keyboard:

- made of polyester, selectively structured

- 5-color back-printing

- display area with color filter for VFD-display

- back side self-adhesive

- 5 pieces gilded snap domes with integrated electrical components (FOILtronic) 2 pieces SMD-LED 20mA-type

- LED-areas transparent matt and unembossed

- key areas high-embossed (pillow- or dome embossing)

- 2 x foil cable, each with crimped socket RM2,54

- laminated onto front side (flush with front side!)

- 100% electr. tested

GH54972.0001/.0002 enclosure made of aluminium

- made of aluminium 2,5 mm

- double-U construction (2 parts)

- with some break-outs

- mounted with countersunk head screw

- electrically conductive chromated

- lacquered RAL 7035 light grey structure

- with monochrome screen process RAL 9005 black

- external dimensions:

550 x 450 x 150 mm - made of aluminium 2,5 mm

- double-U construction (2 parts)

- with some break-outs

- mounted with countersunk head screw

- electrically conductive chromated

- lacquered RAL 7035 light grey structure

- with monochrome screen process RAL 9005 black

Plastic

Transponder unit

Customer-specific enclosure used as receptacle for a transponder unit

Supplied incl. fitting parts, base plate, varnishing and polychrome printing

Problem:

An appropriate enclosure for a transponder unit was required.

Solution:

Design and preparation of drawings based upon printed circuit board provided by the customer. Enclosure made of plastic, with integrated cable feedthrough, transparent bottom part, visible surfaces varnished in light grey and top side

with 2-colour printing